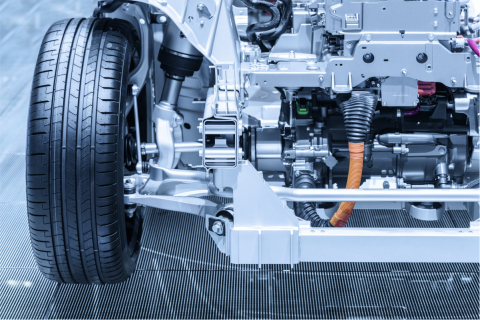

The chassis system manages the dynamic behavior of your vehicle. Its perfect control impacts directly on the driving experience in terms of safety, comfort and efficiency.

What are we doing?

Bitron is market leader of a wide range of chassis products. Thanks to a granitic know-how Bitron is able to develop innovative mechatronics solutions. Our portfolio, constantly innovated by the most advanced technologies, includes a wide range of high efficiency actuators, sensors and accelerator pedals.

Looking at the future

Our research team is focused on the use of lighter materials that reduces weight in order to increase the system performance. In addition, we are upgrading the integration of mechanical and electronic parts, in order to provide more adjustable driving assets

Description

In Bitron, we have a long-term experience in developing and designing totally customizable accelerator pedal modules.

Key features:

- Redundant output with sliding contact or contactless angular sensors

- Mechanical hysteresis

- Kick down option

- Floor mounted and suspended variants

- Specific customer assembly interfaces and pedal ergonomics

Description

Bitron traditional switch with applications like rear/stop light activation or pedal neutral position detection includes now contactless sensors for gears detection, angular speed detection including design with safety relevant characteristics and self diagnosis.

Key features:

- Self-adjustment position by pedal action

- Compact full plastic body with easy lock systems

- Customized connector integrated or wire-to-wire

- Double or single electrical circuits

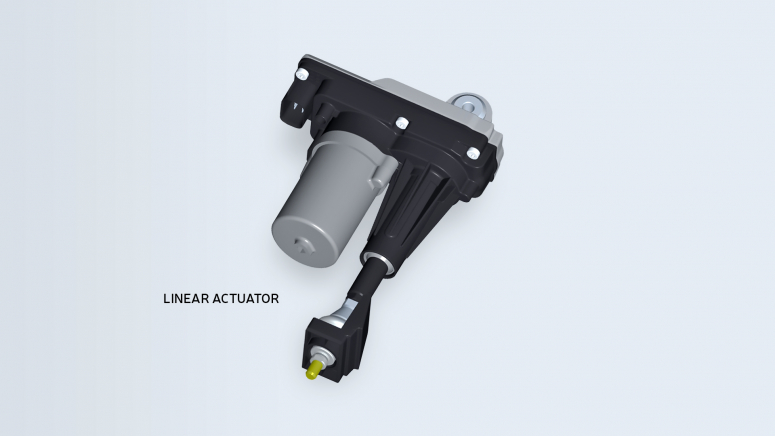

Description

Actuators importance is growing fast in the development of vehicles architecture, with an extraordinary range of applications. Their features cover many critical issues: temperature ranges, actuation forces, integration with electronic, linear and rotary movements. Our actuators portfolio includes applications with DC or BLDC motors, able to integrate position sensors, electronics, and to handle actuators movement via CAN communication.

Key features:

- Full customized design: software, hardware and mechanical

- Integrated BLDC motor

- Full dedicated ECU for motor driving and diagnostic feedbacks

- IP67 compliant

- High speed CAN/LIN communication

- Operating temperature: -20°C+105°C

Description

We have a long-term experience in the development and design of perfectly customizable position sensors.

Key features:

- Angular and linear sensor position

- Analog/digital output

- Programmable output

- Water/dust proof, hydrolysis resistant

- Suitable for harsh environment

Description

Connected to the brake system, Bitron’s brake light sensors are able to detect the exact position of the pedal, whether it is in activated or rest position.

Key features:

- Redundant output for safety purposes

- Contactless switches grant long life expectancy and reliability

- Self adjusting “zero” position during assembly operation

- Fail-safe assembly operation (push and tilt)

- Reusable in case of disassembly

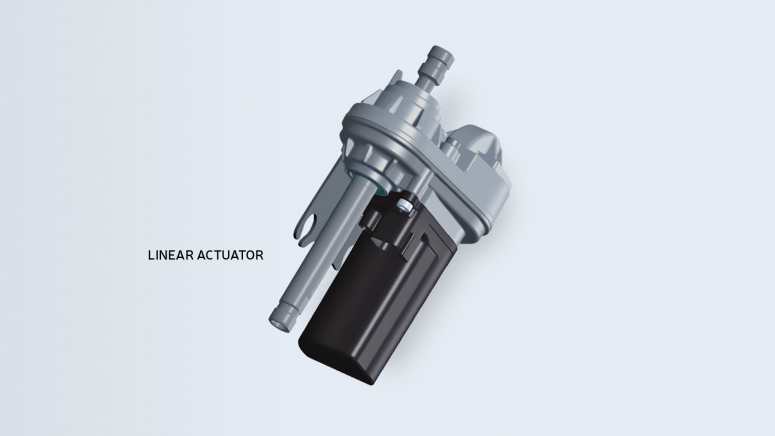

Description

Vacuum sensors and switches are directly connected with the power-brake system, either on brake-booster or on pipeline, and used to activate/deactivate auxiliary vacuum pump on electric vehicles. They also provide the start & stop activation.

Switches key features:

- Normally open / normally closed architectures

- Operating temperature: -40 °C / +125°C

- Nominal working current: 5mA

- Maximum current: 15 mA

- Contact resistance: standard <10 ohm. optional <1 ohm

- Operative life: >500.000 cycles 0/-900 mbar

- Production: ~730.000 pcs delivered in 2013

Sensors key features:

- Double measurement for redundancy

- Pressure range: 0 / 3 bar abs (0 / 43.5 psia)

- Operating temperature: -40°C / +150°C

- Communication protocol: analogic output

- Integrated check valve

Description

The Bitron acoustic warning system is an ultra-compact device capable of producing high level of sound with very low current consumption. Typical application can be reverse-gear warning system, automatic tail gate alert, vehicle welcome sounds. Our device integrates a piezo-electric transducer with a driver that amplifies the signal coming from the body computer.

Key features:

- Ultra-compact Piezoelectric sound generator, with Microcontroller-less architecture

- Full protection against automotive pulses and reverse battery

- Sound generated by Body Computer or two custom defined tones

- Operating Supply Voltage: +10V to +16V

- Sound Level: > 80dBA @ 1m, 13,5V

- Low Current Consumption: <40mA

Description

Bitron’s seat control modules handle the movement of up to ten engines and provides various seat-related comforts. Basing the actuation on relays, we can design silicon-based solution with PWM speed adjustment, providing better comfort and settings accuracy.

Key features:

- Fully Customizable Architecture: Many ECUs developed for different carmakers, with modular solutions to meet each customer need

- Up to 10 seat adjustment motors control, with 3 simultaneous movements and precise position feedback.

- Full Comfort management: Driving of mechanical and pneumatic Massage, Heating, and Ventilation

- Real-time Seat monitoring: with acquisition of multiple external sensors and responsive actuators control

- Advanced Network Management: CAN High-Speed, LIN Master/ Slave, UDS diagnostics and bootloader

- Smart Functions: Memory store/recall, Easy Entry/Exit, Steering Wheel adjustment, “Driver Wake-up” feature

- Safety Functions: ASIL B on critical motor movements, full diagnosis on power output

- Proprietary Anti-Pinch algorithm

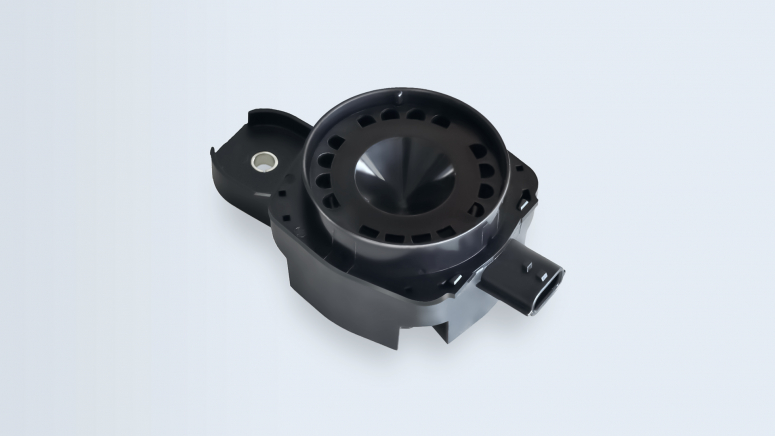

Description

We have upgraded our mechanical switches to contactless sensors. With an improved gear and angular speed detection, their innovative design ensures relevant characteristics in terms of safety and self-diagnosis.

Key features:

- Hall sensor

- ISO 26262

- Sensor with integrated magnet or magnet in the lever

- Zero gauss technology or variable magnetic field