Bitron develops and designs charging technology since 2013

Following the future for a reliable, smarter and emission-free mobility, Bitron offers total EV Charging solutions from E.M.S to compact high quality AC Wall Boxes custom design, to fast DC Modular Charging Stations.

Added Values

- Global EMS supplier

- IATF-certified Manufacturing plant

- Cost engineering team providing complete support for electronic design and VaVe analysis

- ODM with dedicated design engineering team

Our products

Innovation

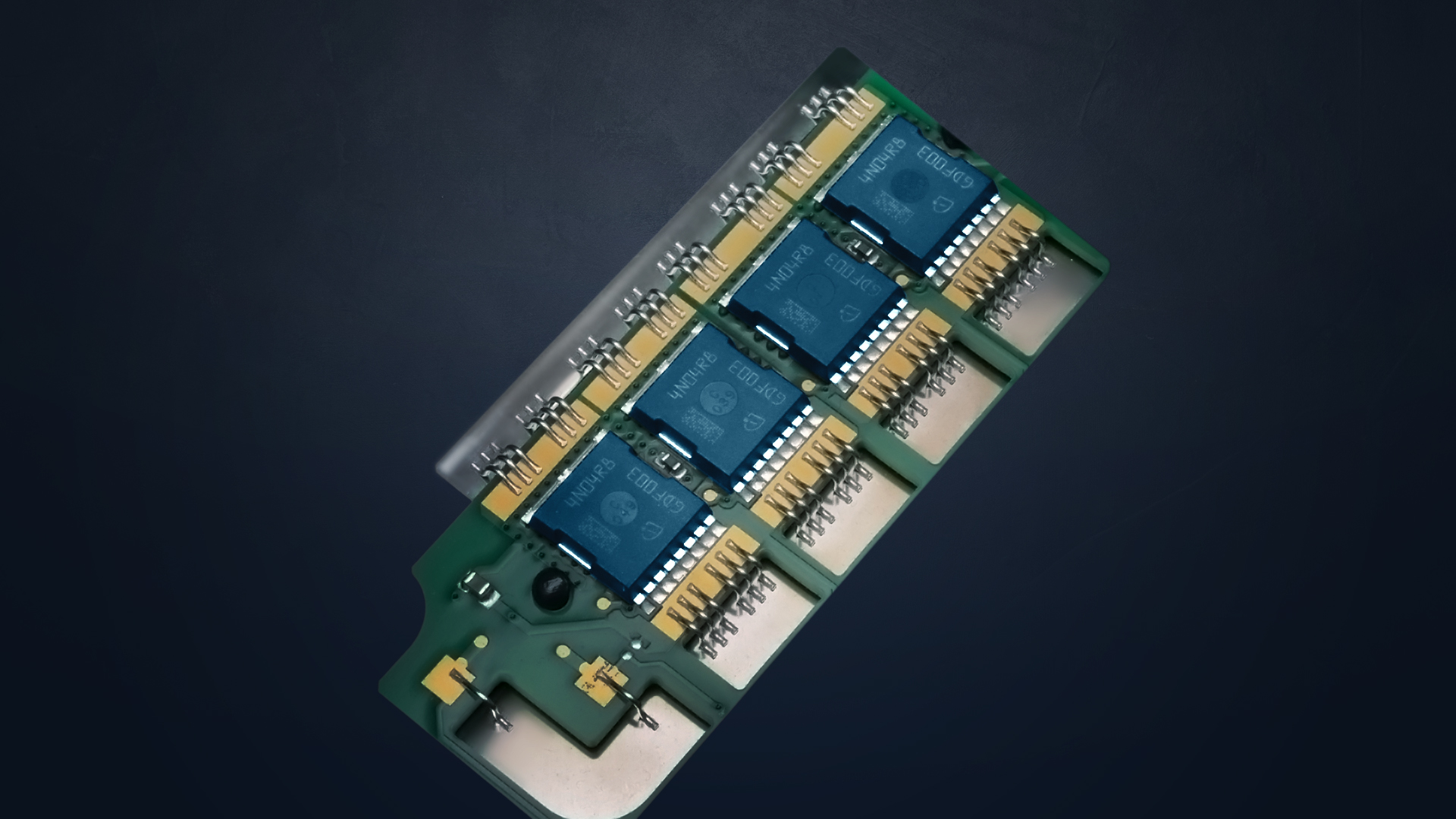

EV charging design & production electronics process requires a new types of manufacturing plant. New automated assembly line, multi-boards, complex mechanical wiring assembly, wire-bonding hybrid technology and sealing resin deposition must be guaranteed with the highest level of quality and repeatability.

Verticalization

We start from engineering electrical design, supply chain risk/performance, testability and this fundamentals drive to mass manufacturing process that results fully integrated. Production cycle time is minimized and optimized and increases production efficiency

Customization

Since the last decades Bitron worked in partenership with global OEM to develop and produce all types of electronics controls and solutions. We’re focused to design and produce charging technology tools that perfeclty fit the industry standards and customer brands.

Electronics Solutions

Bitron team is expert in enhanced manufacturing services in order to shape your mechatronic project into a reliable and engineered solution ready for serial production. Straight focused to system integration and whole systems assembly and testing our added value is much beyond pure electronic manufacturing services.

Our competenciesEach solution is the result of a long commitment of R&D. Our skills and Know – How are always guiding every design and implementation process. Our competences in the EV – charging station industry:AC Vehicle interface (PWM communication)Thermal managementElectrical safetyRemote Connettivity (GPRS/4G)DC, power line and CAN communicationRobustness TestingMultiple boards and subassemblyAutomated manufacturingVxGOCPP for backend communication

TechnologiesWe aim at being protagonist in the automotive electrification transition. For this reason we have done specific investments for this sector, improving our R&D and technologies offering:PCBA assemblyHybrid assembly & Wire bondingPotting electronicsConformal Coating electronics

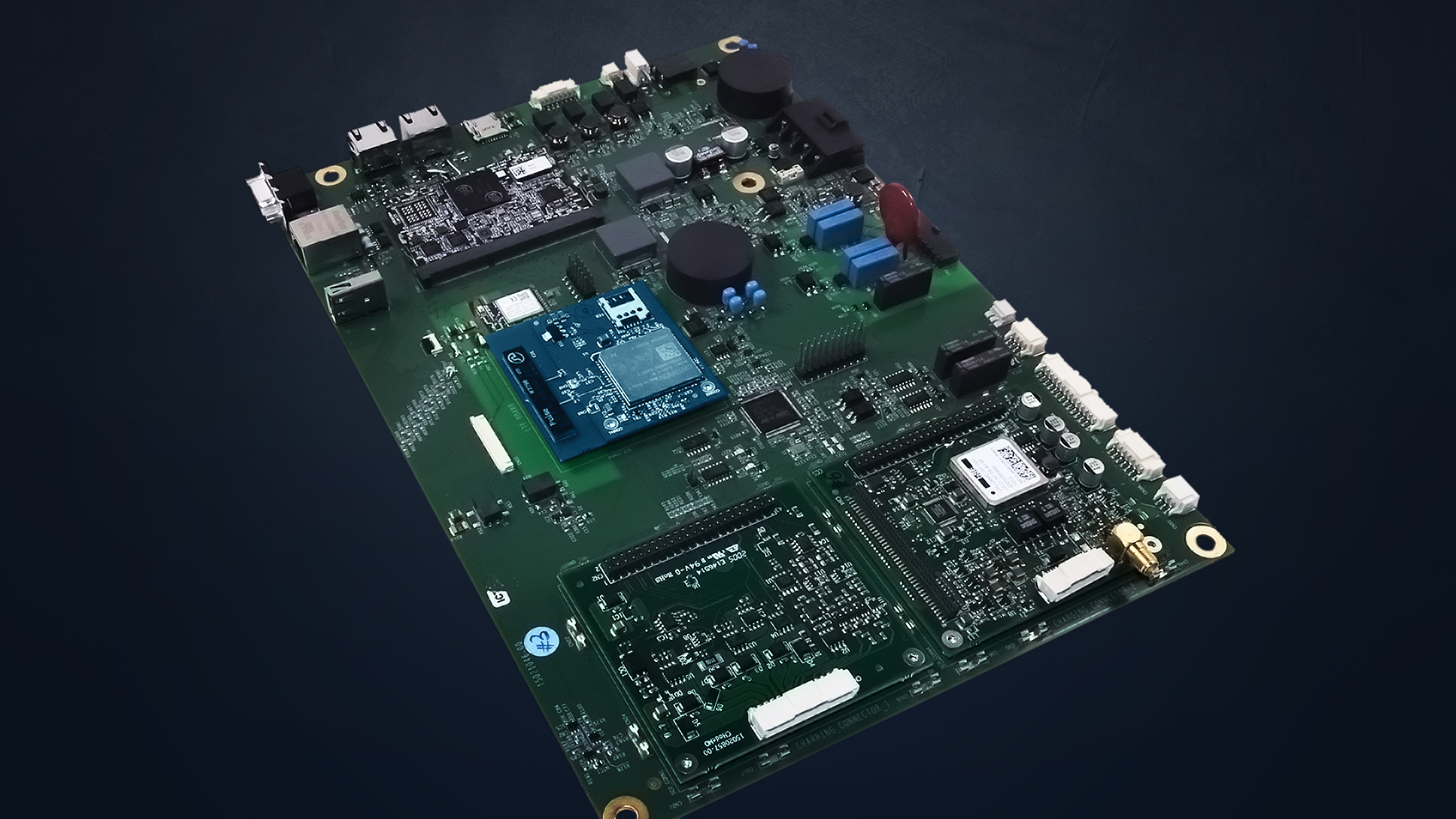

Description

Our AC wall box home & public charging platforms based on an innovative, competitive & affordable charging technology concerning HW & SW. Its design is customized according to our customer requirements with multiple aesthetics options.

Key features:

Only one design that can be declined in all the possible versions

- Mono-phase 3kW, 7kW

- Tri-phase 22kW

- Socket / Tethered

- Aesthetic according to customer design

Modular solution, it’s easy to add/remove functions in order to have many variants

Options:

- Wifi

- Bluetooth

- LTE/4G

- ISO15118

- Display TFT 3.4” with capacitive touch screen

- C2G for power meter communication

- Remote control (OCPP) and on the field upgrade

- Power management system, wallbox as master/slave

If required front plate/mechanics can be customized with different brand or logo

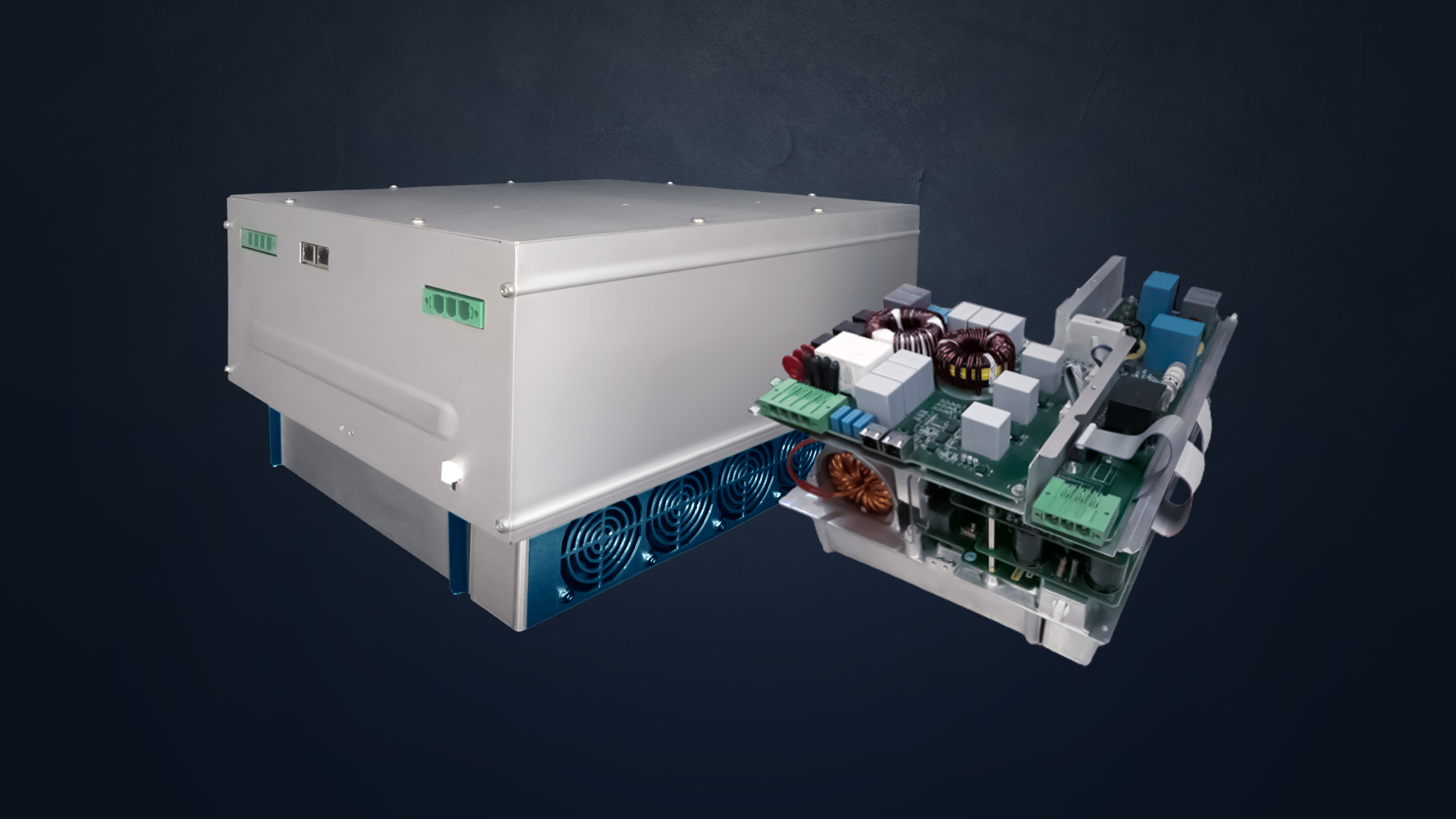

Description

EV Power Module is a compact 25kW AC/DC or DC/DC converter for Electric Vehicle charging applications and is designed exploiting new SiC (Silicon Carbide) technology. This device finds its strong point in a great compact and optimized component management, in order to provide a very small size.

Key features:

- 25kW continuous output power

- Bi-directional version

- 60A output current

- DC output voltage from 50Vdc to 500Vdc

- Stackable output for 1000Vdc output voltages supporting todays and tomorrows charging applications

- EMC Class B according to IEC 61851-21-2

Description

Our AC wall box home charging platforms based on an innovative, competitive & affordable charging technology concerning HW & SW. Its design is customized according to our customer requirements with multiple aesthetics options.

Key features:

- Charging Mode: Mode 2 – IEC61851

- Rated Current: up to 32A

- Voltage: 230V (1-phase) or 400V (3-phase)

- Maximum charging power: Up to 22 kW

- Charging connector: Type 1 or 2

- Socket or cable version available

- Integrated Protection: RCCB DC 6 mA/30 mA r.m.s

- Standard connectivity options: WIFI/BT

- Optional connectivity: 4G Lte, RFID, ISO15118, CHAIN2

- Support for Plug and Charge (ISO15118 option)

- Power load management with communication to house power energy meter (CHAIN2 option)

Member of: