Bitron is a leading manufacturer of a wide range of products used for the manufacture of washing machines and dryers.

Applications include water control (solenoid valves and safety systems), detergent and liquid distributors, bulk dispensing devices, water softeners, doorlocks, various types of switches and sensors (including pressure sensors) as well as a comprehensive range of electronic main control-boards and user interfaces. We are available for the development of customized solutions.

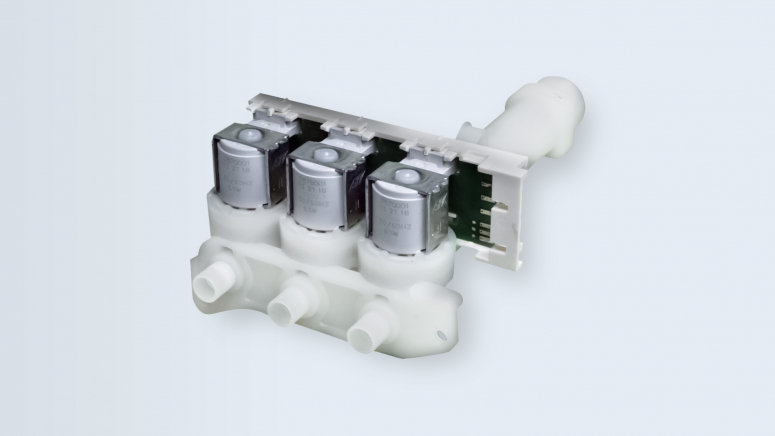

Description

Water inlet and safety valves control the water flow into an appliance. Bitron has become the leading solenoid valve supplier to the worldwide appliance market and supplies domestic, professional and industrial markets. Typical valves for washing machine are multiple outlet type. Bitron safety valves can be single or double valves in series, as well as double hose to detect hose leakages leaving the hose water pressure relieved during off time. Complex hydraulic circuits may include a motorized diverter in order to reduce the number of valves, connections between inputs and outputs, and pressure losses.

Key features:

- Solenoid valve bodies: from 1 to 2 inlets and from 1 to 6 outlets

- Safety valves: from 1 to 2 valves, with protective hose and nut. Electric and Pneumatic actuator

- Operating pressure range: 0.02Mpa up to 1Mpa

- Standard Working Temperatures: ambient max.60°C;medium 90°C;storage -30/+80°C (on request could be customized)

- Power supply: DC or AC, from 12V to 380V

- Flow regulator: from 0.25 L/min to 20 L/min

- Electrical connections: Rast 2.5; Rast-5; fast-on 6.3x0.8 mm

- All major approvals

- Sensors: flow, temperature

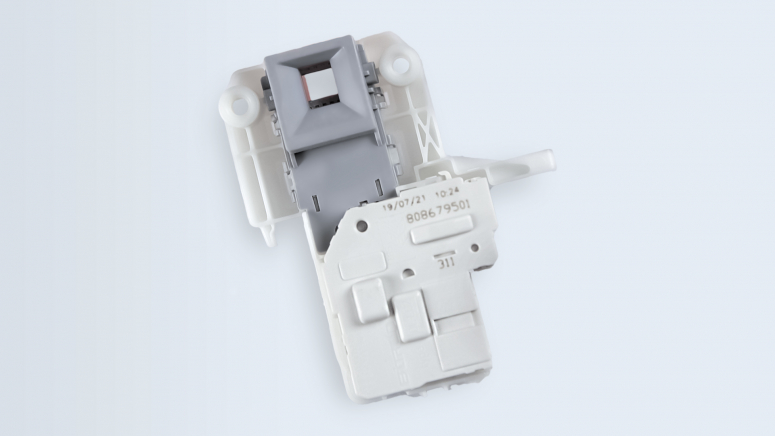

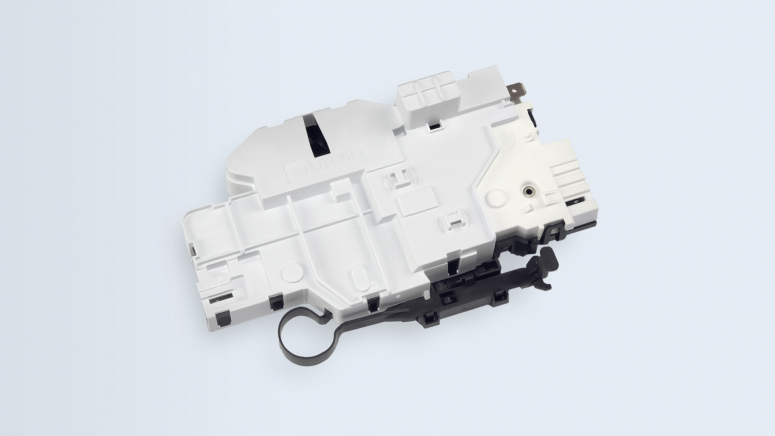

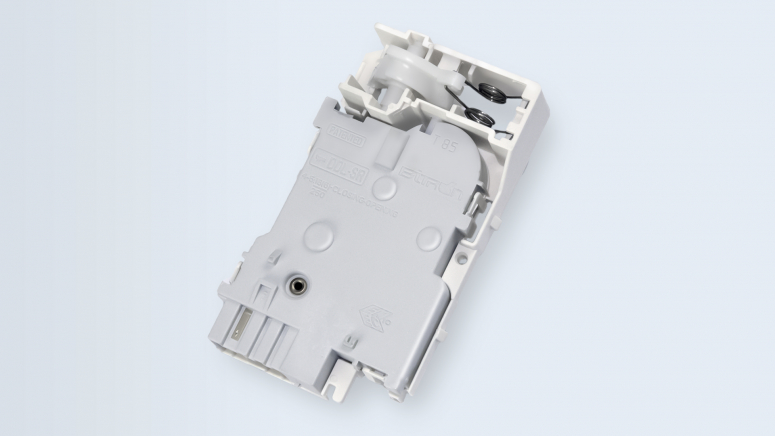

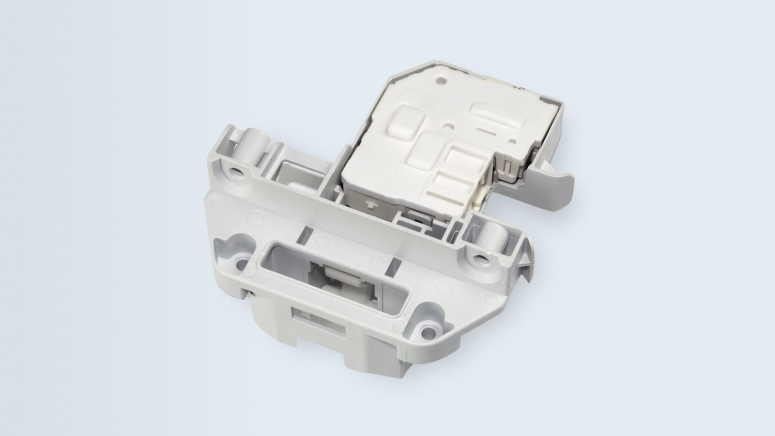

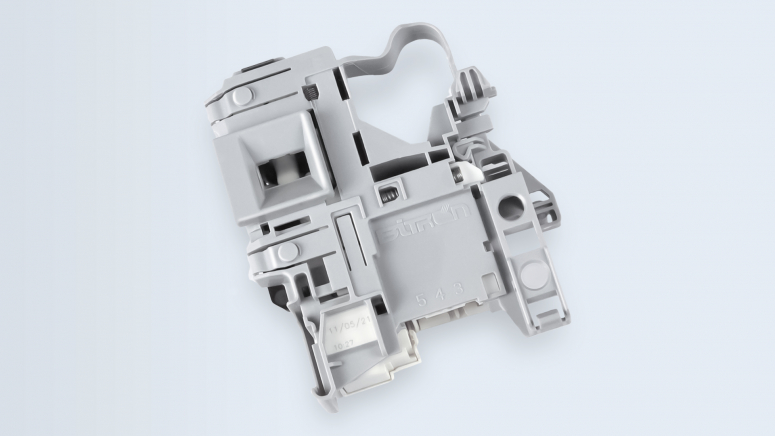

Description

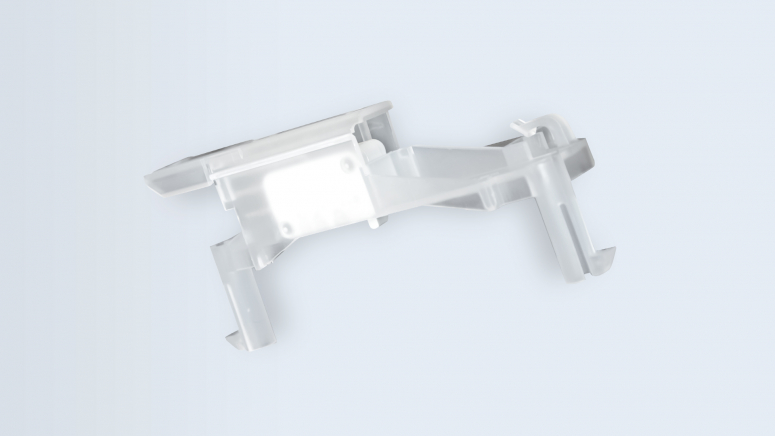

Several standard and customized product families are available for washing machine and dryer door locking and latching applications. Electrical box may be PTC delayed, with or without ambient temperature compensation or instantaneous operated by solenoid actuator with safe mechanism against input failure or motorized doorlocks. Solutions for Pull to open, Push to open or door with handle are available in our portfolio.

Key features:

- Rated voltage from 12V DC to 120/250 V AC

- Further solutions can be developed in co-design with the customer

- Mechanical Interface with appliance is customized according to customer request

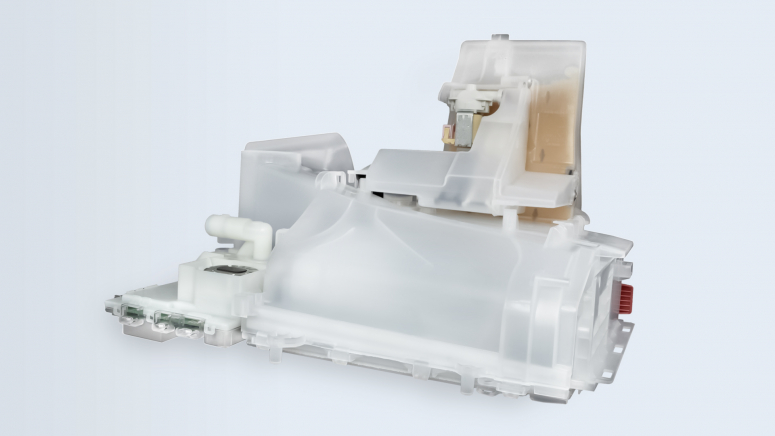

Description

Bulk dispensing of liquid detergent and fabric conditioner. Peristaltic pumps with lifelong high-precision flow rate. Optimized consumption and washing performance. Customized systems with level sensors and electronic control for automatic dispensing

Key features:

- Flow rate: from 27 cc/min to 100 cc/min

- Lifetime maintenance-free self priming pumps

- No check valve required

- Flow rate is independent from voltage fluctuations and liquid viscosity

- Voltage supply: mains voltage and low voltage

- Level indication: by optical sensor

- Detergent capacity: approx. > 1000 cc

- Fabric conditioner capacity: approx. > 700 cc

Key features:

- Ion exchange resin softens the water used in wash and rinse cycles

- Improves color brightness and fabric life

- Minimizes detergent and energy consumptions due to water hardness

- Resins regeneration made by salt

- Sensors for water flow and water hardness (options)

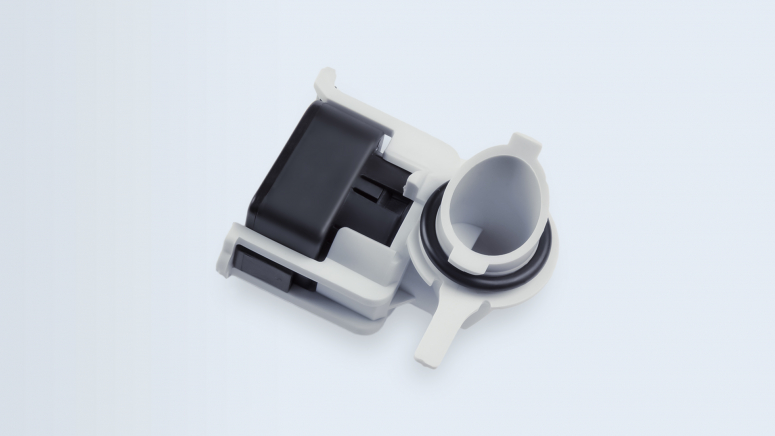

Description

The Analogue Pressure Sensor is an inductive sensor (LVDT) that measures precisely the pressure and allows the control of the water level inside the washing machine or dishwasher. The “in circuit” calibration gives a customized output characteristic. No software is needed in the main circuit, a hardware internal control (Periodic Self-Test) of the device ensures that the sensor is equivalent to a class B.

Key features:

- Power supply 5V+/-05

- Resolution 0.3 mmH2O (3Pa)

- Negative pressure measurement possible

- Calibration: calibrated in five points all over the range

- Pressure ranges: from 0-200mm H2O (0-2000Pa) to 0-600 mm H2O (0-6000Pa)

- Frequency output is independent from the supply voltage; ranges from 26kHz to 10Hz

- Voltage output available

Description

Bitron produces a wide range of switches and sensors for washing machines and dryers. Special sensors can be developed according to customer requirements.

Key features:

- Microswitches: high & low activation force (ie. from 10g to 400g)

- Floaters for safety valves & other applications

- Pressure switches for high & low pressures

Sensors, several types are available for:

- Position detections: on different conditions and applications

- Water parameters such as: flow, pressure, level, temperature, conductivity, turbidity, hardness

Description

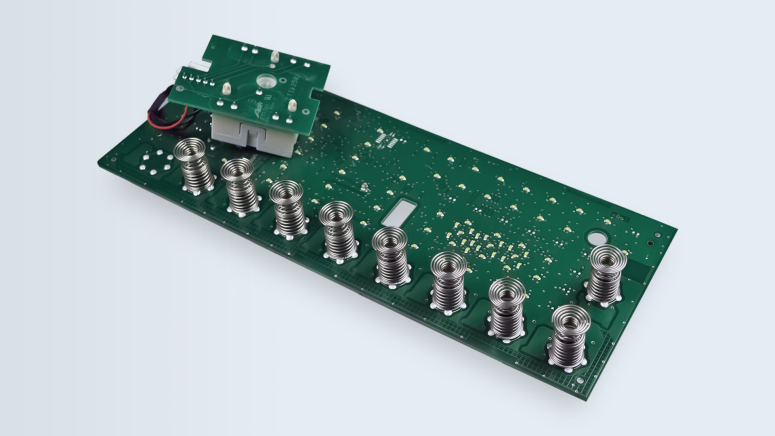

User Interfaces for Washing machines and Dryers

Key features:

- Embedded 32-bit microcontroller with TFT/LED image database memory

- TFT/LCD or LED module driving

- RGB LED driving incl. Light effects

- Low-cost customized LED modules

- LCD with icons, digits, full graphics

- TFT with or without embedded touch

- Dynamic TFT image management

- Knob with integrated display

- Connectivity WiFi/BLE/NFC embedded

- Capacitive touch/input interface

- Single or multi-key functions

- Water/steam proof touch algorithm

- Aesthetic panel design and manufacturing

- Knob, light ring, TFT frame

- Chrome finishing, soft feel finishing

- PC film with tampon printing

- In-mould decoration

- Back housing frame for PCBA and HMI front

- Integrated gasket and sealed cable outlet

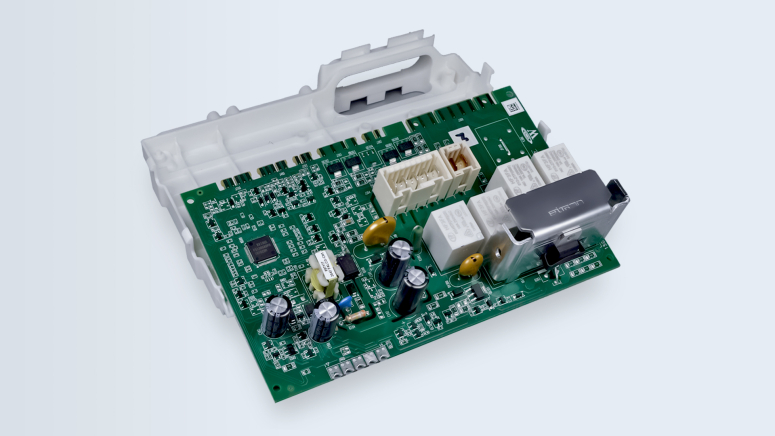

Description

Main boards for Washing machines and Dryers

Key features:

- 32-BIT MCU for whole machine management

- DC load driving (ON/OFF and PWM)

- AC load driving

- Low standby energy consumption

- EMI/EMC filter embedded

- DC sensors management for temperature, turbidity, hardness

- AC/DC signal inputs for door sensing, digital input and analog sensing

- Data communication WiFi/BLE/serial

- HMI/UI/remote boards connections (supply and insulated data communication)

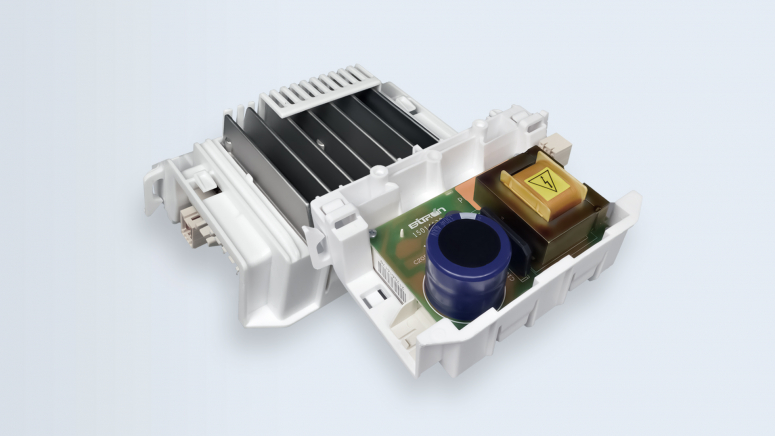

Description

Inverter for Washing machines brushless motors and Dryer compressors brushless motors

Key features:

- Efficiency >97% (full load)

- Synchronous motor (BLAC/BLDC)

- Discrete or IPM power stage topology

- Sensorless motor driving algorithm available

- Embedded EMI/EMC filter for optimal noise rejection compliance

- Embedded PFC (active or passive) compatible with EN 61000-3-2

- US, EU, emerging markets or extended range voltage input

- Low stand by consumption solutions

- Plastic housing fitting on machine / or motor shell

- Custom heatsink design

- Thermal management solutions