In Bitron, we strongly believe that the motorcycle world demands for more innovative and customizable solutions. Therefore we are aiming at improving our entire dedicated product portfolio with a clear scope: increasing efficiency.

What we are doing Our core business, in the motorcycle sector, is characterized by 2 macro - families. The first one is the Fuel Management System: our fuel pumps and fuel level sensors are perfectly customized for all thermal engine types. The second one is the sensors family, with contactless technology. In addition, together with our customers, we have developed our electronic throttle grips, electronic valves (oil and air), height sensors for suspensions and the electric actuators, with various application such as windshields.

Looking at the future We develop and produce our products always thinking of two fundamental elements: the driver safety and the efficiency of the vehicle in all its parts. For this reason we are concentrating our resources in order to improve the human - machine interface to ensure the rider the perfect control of his bike. In addition, with the aim of accelerating the transition process to zero emission mobility, we are focusing our efforts to improve charging and battery management system performances.

Description

We have shaped our throttle grips to provide the higher level of comfort while riding. In addition, they can be standard or heated and both already integrated with accelerator position sensors.

Key features:

- Redundant output with contactless angular sensors.

- Mechanical hysteresis.

- Cruise control cancel option (negative stroke).

- Standard and heated grips.

- Customer specific grip texture.

Description

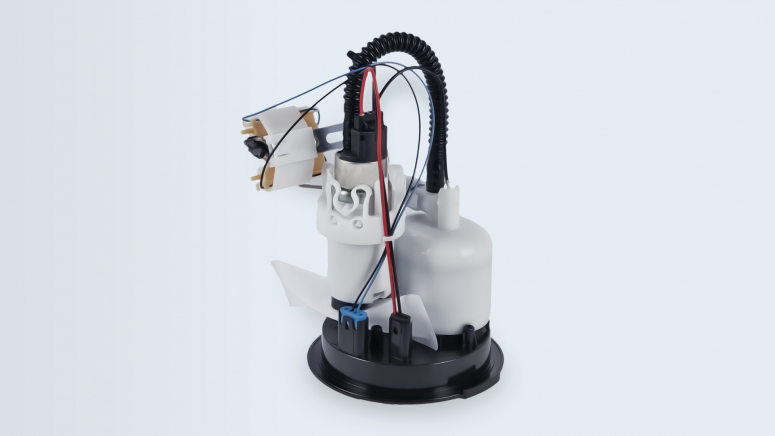

Our fuel pump modules are suitable for all type of motorbikes: street, sport, enduro, off-road and scooters (2-3 wheels).

Key features:

- Compact size.

- Wide range of applications: high performance (big engines), low current consumption (small engines).

- Plastic flanges with integrated electrical connectors.

- Returnless or 2-ways configurations.

- Optimized layout for tank geometries.

- Mechanical pressure regulator or electronic driver.

- Arm or tubular fuel level sender integrated.

Description

According to our customers needs we can adapt our tubular fuel level senders length in order to integrate them in every fuel pump modules.

Key features:

- Fuel level signal; fuel low level signal.

- Electrical part in the upper zone (suitable for fuels type e22).

- Modularity – available 150 to 210 mm length.

- High reliability.

- Plastic flange with electrical connector integrated.

- Excellent contact pressure.

- Reduced blades displacement (reduced wear).

- Integrated signal damping (calibrated hole).

- High resolution (over 60 steps).

- Double-face resistance to improve the scooter tank adaptability.

- Direct in-tank assembly without additional flange.

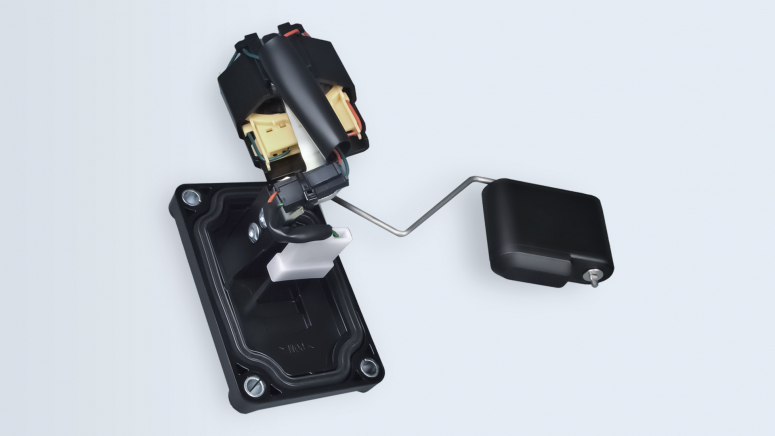

Description

Stand alone arm fuel level sender, integration in a complete fuel pump modules is an option

Key Features

- High resolution (up to 60 steps).

- Customizable float and arm.

- Customizable ohimoc range

- Working angle from 45° to 100°.

- Suitable for fuel type E30/M15.

- Integrated electrical connector

- Weight, about 150 g.

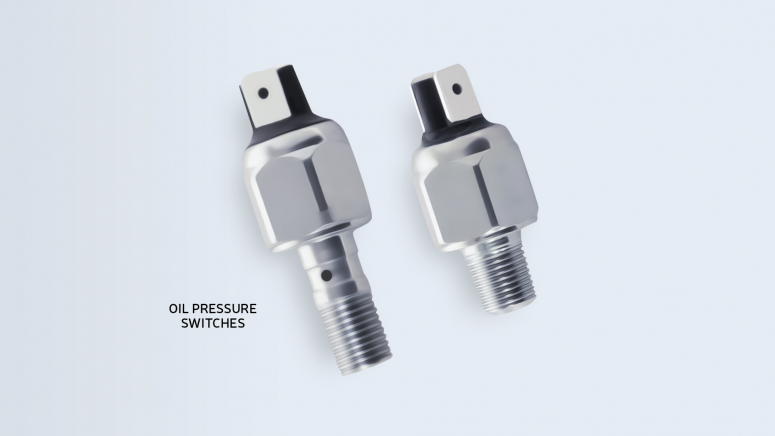

Description

We have designed and developed our switches and sensors to provide the widest range of application. They are manufactured for all type of 2-wheels vehicles.

Key features:

Oil Pressure Switches

- Scooters and motorcycle applications.

- Single level pressure switch for low pressures.

- Small sizes; high reliability; calibration stability.

- Single wire electric connection.

- Filter version available.

High Level Pressure Switch

- Suspensions system application for scooters.

- Hydraulic stop light switch for motorcycles.

- Single level switch.

- Small sizes; high reliability.

Linear Position Sensor

- Gear sensor for motorcycles.

- Hall-effect technology.

- High temperature resistant.

- Working in a oil bath.

Description

Our solution in terms of canister valve is an on/off pwm controlled solenoid valve for fuel vapor canister purge. The function of the evap purge ev is to regulate purge flow of fuel vapors from the charcoal canister to the intake manifold.

Key features:

- 3-2 nC or 2-2 nC valve.

- Supply voltage: 13.5 V, 10Hz (PWM).

- Pressure rang: -600 mbar in passing direction, 1 bar in non passing direction.

- Coil resistance: 21 ohm.

- Flow rate: up to 5 kg/h at dp = 200mbar to 600mbar.

- Temperature: -40ºC to 140 ºC.

Description

Rotative Actuator designed and developed for wide range of applications.

Manufactured for all type of 2-wheels vehicles.

Key features:

- High vibration resistance

- IP6k7k

- PWM

- 360° rotation

- Low current assumption DC Motor

- Max Torque 5Nm

- Operation Temperature: -20° +80°

- Customized interfaces of the output shaft

Under development

- High-performances variants

- LIN or CAN

- ODB capable through absolute encoder

- EMC optimization of hardware and software

- ASPICE development

Description

The Gear Position Sensor detects the position of the gear, such as first or second, and sends the data as electric signal to the ECU to adjust engine parameters such as fuel injection timing, ignition timing, and other factors based on the current gear position

It is based on a contactless technology (Hall Effect), thus avoiding sliding contacts, subject to damage from collision and wear.

Key features:

- Operation Voltage: 5.0 V

- Operation Temperature Range: -20°C ~ + 120°C

- High level Vibration resistance

- High level Chemical resistance

- Sensor body waterproof: IP69X

- Small dimensions and weight

- Easy assembling

Description

The Shift Shaft Sensor detects the movement of the gear shaft and the data as electric signal to the ECU to momentarily cut ignition or fuel delivery to ensure smooth gear changes without causing driveline shock or engine damage.

It is based on a contactless technology (Hall Effect), thus avoiding sliding contacts, subject to damage from collision and wear.

Key features:

- Operation Voltage: 5.0 V

- Operation Temperature Range: -20°C ~ + 120°C

- High level Vibration resistance

- High level Chemical resistance

- Sensor body waterproof: IP69X

- Very Small dimensions and weight

- Easy assembling

Description

The thumb throttle accelerator is designed for cross-country motorcycles with internal combustion engines. It operates by rotating the lever, providing intuitive and responsive control.

This module features a dual Hall sensor system within a contactless sensor and includes a redundant spring mechanism to meet stringent safety requirements.

Key features

- Ergonomics tunable as per customer requests (apply load, mechanical

- hysteresis, angular stroke…)

- Dual Hall sensor

Technical features

- Supply voltage: 5±0.1V

- Redundant analogue output (S1, S2)

- Operating Temp: -40°C / +85°C

- Endurance: 1,000,000 cycles

- IP Level: IP5X

- Angular Displacement: 0° ~ 42°

Functional Characteristics

- Linearity of S1 and S2 <=+/-2%Vcc

- Synchronization of S1 and S2<=+/-3%Vcc

- Max current consumption: 30mA

- Pull down resistance required (ECU side):

- Out Gas Pos.1: 20 KOhm±5%

- Out Gas Pos.2: 10 KOhm±5% (TBD)