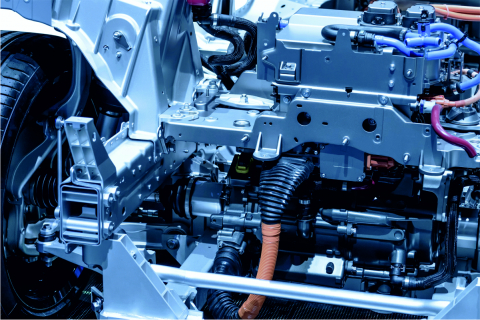

At Bitron, we consider the Powertrain the car’s hearth. Our passion guides us in developing components that manage the vehicle fluids, mandatory for the correct beat of the car. In this way, we are sure to guarantee the user satisfaction giving our contribution for the environment sustainability.

What we are doing Our complete portfolio of solenoid valves, actuators, switches and sensor assures us to provide adaptable solutions for all systems.

Looking at the future The world is changing fast and Bitron is working to be part of this change. We want to give a concrete help to our customers during the transition into the e-mobility era. To achieve our goal, we have managed to optimize weights, materials and power consumption of our components.

Technologies

In Bitron every detail values. For this reason, we have decided to internalize all key core technologies to develop and produce our products. In this way, we are sure to have control of all processes of our components, from the idea to it's realization:

Automatic coil winding

Injection molding department with several molding machines (horizontal and vertical), robots & automation for metal insert overmolding

CAD/CAE systems for design, simulation & digital mock up

Laser welding to join plastic component with robust and waterproof connection

Laboratory testing equipment for product development and validation

Description

One of our most diversified family. The protagonist is the air, core element for this specific type of valves. It includes clean air, vacuum, gasoline vapors, dirty air from carter among others. The main applications are by-pass EGR, waste-gate, dump valve, TGV, purge, cold start, Carter purge. We keep investigating this branch of systems to discover new ways to reduce gasoline consumption in Hybrid cars.

Key features:

- 3/2 or 2/2 ways

- High flow rate with low pressure loss depending the application

- High operating pressure

- Operating temperature up to 140 °C

- Max vibration: 40g

- Chassis or engine mounting

- Life: 110,000,000 cycles

Description

One of our most important families, solenoid valves to drive coolant for cooling or HVAC systems. Includes 2 ways, 3 ways valves. There is also the possibility to introduce new concepts providing sensors for diagnostic capability, less weight and less consumption with the overall advantage for the system designer.

Key features:

- 2-2 / 3-2 / 4-2 ways on-off solenoid valve

- Max. switchable pressure: up to 1 bar*

- Operating voltage: 13,5 V

- Coil resistance: 10,5 ±10% ohms

- Operating temperature: - 30 to 125°C

- Flow rate : 9 – 25* l/min with ∆p 300 mbar between inlet and outlet and 25⁰C

- Flow: coolant 50:50 (water/glycol + additives)

- Max. circuit pressure: 3 bar

- Life: 300.000 cycles

Description

The valves represented in this family work together with the oil pump to provide a less fuel consumption. To reach this achievement is possible only with the perfect collaboration between these two components.

Key features:

- 3-2 on/off or proportional

- Failsafe available

- Current up to 1A

- Flow 4 l/min

- Operating temperature: - 40 to 145°C

Description

Our newest solenoid valve family. Working with high pressure refrigerant, in gaseous or liquid state, our valves can stand high pressures to provide high flow rates. Our technology allows to build smaller solenoids, with the clear advantages in the component weight.

Key features:

- 2-2 ways on-off nc and no solenoid valve

- Refrigerant continuous pressure up to 2,5 mpa

- Refrigerant t: - 38 to 100° C. peaks 130 Cº

- Massive flow rate inlet imposed 200 Kg/h -> pressure inlet 120 Mbar

- Max. circuit pressure: 30 bar

- Life: 130,000 cycles

Description

We have taken steps forward to evolve this family, looking for the highest standard level. All our solenoid valves can make precise diagnosis. In addition, smart motorized valves, developed for thermal management with intelligent power consumption, provide a complete control of the system.

Key features:

- Smart valve with position sensor feedback

- Smart valve possibility

- Communication through CAN LIN or PWM

- Stepper motorized valve

- 4/2 or 3/2 ways valve

- 12 v or 24 V versions

Description

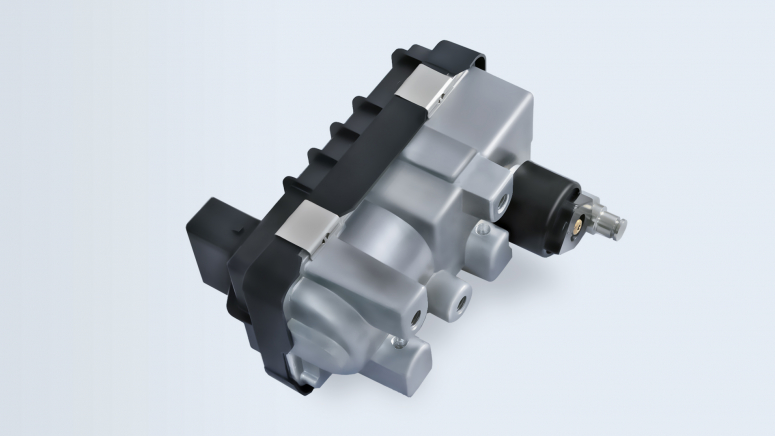

We have developed the actuators family to achieve several applications like automatic gearboxes, shift locks and active suspension. Our motorized actuators are able to provide the last safety standards, mandatory for electrical vehicles.

Key features:

- On/off 2 position or proportional electromagnet

- Supply voltage: 10-16 V

- Plunger course: 6 mm

- Temperature up to 150°C

- Force up to 100 N (depending plunger position)

Description

We design and product fully customized pressure sensors, ready to be integrated in every powertrain system and to control hydraulic actuators.

Key features:

- Small sizes, high reliability, calibration stability

- Hydraulic sealing during lifetime

- Electric and mechanic connections according to customer requirements

- Filter version available

- Wide range of fluids allowed

Description

Dual Battery Switch Module for new hybrid vehicles for fuel saving and emissions reduction. Automatic fault mitigation strategies based on «reduced performance» in case of system failures.

Key features:

- Ambient temperature: 40°C up to +105°C

- Switching current: up to 150 A

- High Speed CAN communication with vehicle body computer

- Water & Dust Protection: IP6K9K

- ASIL C (ISO 26262) regulation compliant

- Dedicated temperature sensors for fault mitigation mechanism